Are you wondering if metal is eco-friendly? Well, you’re in the right place! In this article, we will explore the environmental impact of metal production and recycling. We’ll also compare the carbon footprint of metal to other materials and delve into the sustainable practices being implemented in the metal industry. Plus, we’ll highlight some exciting innovations that are making metal manufacturing more eco-friendly than ever before. So sit back, relax, and get ready to discover how metal can be a sustainable choice for our planet.

The Environmental Impact of Metal Production

Metal production has a significant environmental impact due to its high energy consumption and greenhouse gas emissions. The process of extracting, refining, and manufacturing metals requires large amounts of energy, primarily from fossil fuels. This energy consumption contributes to carbon emissions, which are a major driver of climate change. According to the United Nations Environment Programme (UNEP), the metal industry is responsible for around 10% of global carbon dioxide emissions.

In addition to carbon emissions, metal production also poses a risk to water sources through pollution. During the extraction and processing stages, various chemicals are used that can contaminate nearby water bodies. Heavy metals such as lead, mercury, and cadmium can leach into rivers and lakes, posing risks to aquatic ecosystems and human health.

One example of water pollution caused by metal production is acid mine drainage (AMD). AMD occurs when sulfur-bearing minerals in ore deposits are exposed to air and water during mining operations. The resulting chemical reactions create highly acidic water that can flow into nearby streams and rivers, damaging aquatic habitats and affecting downstream communities.

Overall, the environmental impact of metal production cannot be overlooked. It contributes significantly to carbon emissions and poses risks for water pollution through various stages of the manufacturing process.

Metal Recycling and Its Benefits for the Environment

Recycling aluminum, for instance, has a positive impact on the environment. Metal recycling technologies play a crucial role in reducing metal waste and promoting a circular economy in the metal industry.

When you recycle metals like aluminum, you are contributing to the conservation of natural resources. Mining and extracting new metals have significant environmental consequences, including deforestation and habitat destruction. By recycling aluminum, you can reduce energy consumption by up to 95% compared to producing it from raw materials. This not only saves valuable energy resources but also reduces greenhouse gas emissions associated with metal production.

The benefits of metal recycling extend beyond environmental conservation. Recycling metals helps create jobs in the recycling industry while also saving money for manufacturers who use recycled materials instead of virgin metals. Furthermore, it reduces the need for landfill space by diverting metal waste from disposal sites.

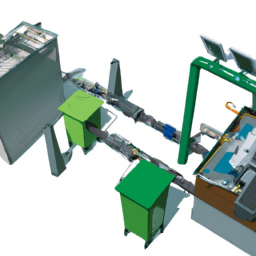

In recent years, advances in technology have made metal recycling even more efficient and cost-effective. Innovations such as electromagnetic separation techniques and plasma arc cutting allow for better sorting and processing of different types of metals.

Comparing the Carbon Footprint of Metal Vs. Other Materials

When you compare the carbon footprint of metals to other materials, you’ll find that metals often have a lower environmental impact. This is because metal production tends to be more energy efficient compared to the production of other materials. Metals can be melted down and recycled repeatedly without losing their properties, which reduces the need for energy-intensive extraction and processing. Additionally, modern metal manufacturing processes have become increasingly efficient, minimizing energy consumption during production.

In terms of waste management, metal manufacturing processes also fare well. Many byproducts and waste materials generated during metal production can be recycled or reused. For example, slag, a byproduct of steelmaking, can be used in road construction or as an ingredient in cement production.

Furthermore, advancements in technology and regulations have compelled metal manufacturers to adopt cleaner and more sustainable practices. These include implementing measures to reduce emissions and investing in technologies that capture pollutants before they are released into the atmosphere.

Overall, when considering both energy consumption and waste management aspects, it becomes clear that metals have a relatively low environmental impact compared to other materials. However, continuous efforts should be made within the industry to further improve sustainability and minimize any negative effects on the environment.

Sustainable Practices in the Metal Industry

Advancements in technology and industry regulations have led to the adoption of cleaner and more sustainable practices within the metal manufacturing sector. Sustainable mining practices, such as responsible sourcing and reducing water consumption, are becoming increasingly important considerations for metal producers.

One key area where the metal industry is focusing on sustainability is in mining operations. Sustainable mining practices aim to minimize the environmental impact of extracting metals from the earth. This includes using techniques that reduce energy consumption, limit greenhouse gas emissions, and protect ecosystems.

Reducing water consumption is another crucial aspect of sustainable metal manufacturing. The metal industry has been implementing various strategies to conserve water during production processes. For example, companies are investing in technologies that recycle and reuse water instead of relying solely on freshwater sources. Additionally, innovations like dry processing methods minimize or eliminate the need for water altogether.

These efforts towards sustainable mining practices and reducing water consumption demonstrate a commitment by the metal industry to mitigate its environmental footprint. By adopting these practices, manufacturers can not only reduce their impact on natural resources but also contribute to a greener future for all.

Innovations in Eco-Friendly Metal Manufacturing

To make your metal manufacturing process more sustainable, you can explore innovative techniques that prioritize environmental friendliness. One such innovation is the development of sustainable metal alloys. These alloys are designed to have reduced environmental impact throughout their lifecycle, from production to disposal. By using recycled materials and optimizing manufacturing processes, these alloys minimize resource consumption and waste generation.

In addition to sustainable metal alloys, another promising innovation in eco-friendly metal manufacturing is the use of green metal coatings. Traditional coatings often contain harmful substances like volatile organic compounds (VOCs) that contribute to air pollution and health hazards. Green coatings, on the other hand, are formulated with low or zero VOC content, making them safer for both workers and the environment.

By incorporating these innovations into your metal manufacturing process, you can significantly reduce its ecological footprint. Sustainable metal alloys and green metal coatings not only help preserve natural resources but also contribute to improved air quality and worker safety.

Several studies have shown the effectiveness of these innovations in reducing environmental impact without compromising performance or quality. For example, research has demonstrated that sustainable metal alloys can exhibit comparable mechanical properties to conventional counterparts while requiring fewer raw materials and energy during production.

Frequently Asked Questions

What Are the Main Environmental Concerns Associated With Metal Production?

When it comes to metal production, there are several environmental concerns that need to be addressed. One of the main concerns is pollution control. The process of extracting and refining metals can release harmful pollutants into the air, water, and soil. These pollutants can have serious consequences for ecosystems and human health. By implementing effective pollution control measures, such as using cleaner technologies and properly disposing of waste products, we can minimize these environmental impacts and make metal production more sustainable.

How Does Metal Recycling Contribute to Reducing Greenhouse Gas Emissions?

Metal recycling plays a significant role in reducing greenhouse gas emissions. By recycling metal, we can save energy and reduce the need for mining and extracting new raw materials. The process of recycling metal produces fewer emissions compared to the production of virgin metal. However, there are also challenges involved, such as the collection and sorting of scrap metal. To promote metal recycling, governments can implement policies that incentivize recycling efforts and provide support to industries engaged in sustainable practices.

What Is the Carbon Footprint of Metals Compared to Other Commonly Used Materials?

When considering the carbon footprint comparison of metals, it is essential to conduct an environmental impact assessment. This evaluation allows for a detailed examination of how different materials contribute to greenhouse gas emissions. Metals, such as steel and aluminum, generally have a lower carbon footprint compared to other commonly used materials like plastic or concrete. This is due to their high recyclability rates and energy efficiency during manufacturing processes. These findings provide evidence that choosing metal can be more eco-friendly in certain applications.

Are There Any Specific Sustainable Practices That the Metal Industry Can Adopt to Minimize Its Impact on the Environment?

To minimize its environmental impact, the metal industry can adopt various sustainable practices. These include implementing energy-efficient technologies in production processes, reducing waste through recycling and reusing materials, and promoting responsible sourcing of raw materials. By implementing these practices, the industry can significantly reduce its carbon emissions and resource consumption. Additionally, investing in research and development for greener alternatives and improving overall efficiency can further contribute to a more eco-friendly metal industry.

Are There Any Recent Innovations in the Metal Manufacturing Industry That Are Focused on Being More Eco-Friendly?

Recent metal innovations and sustainable metal practices have become increasingly important in the manufacturing industry. Companies are actively exploring new technologies and methods to minimize their environmental impact. For instance, there have been advancements in recycling processes that allow for more efficient use of metal resources. Additionally, some manufacturers are implementing renewable energy sources to power their facilities, reducing carbon emissions. These eco-friendly initiatives demonstrate a commitment to sustainability within the metal manufacturing industry.

Conclusion

In conclusion, metal can be considered as an eco-friendly material due to its recyclability and sustainable practices in the industry. The environmental impact of metal production is a significant concern, but metal recycling has proven to be effective in reducing waste and conserving resources. Moreover, when comparing the carbon footprint of metal with other materials, it becomes evident that metals have lower emissions. With ongoing innovations in eco-friendly metal manufacturing, the industry continues to strive towards more sustainable practices for a greener future.